The development of cutting die technology and manufacturing techniques ensures the most efficient and accurate die-cut box design. Typically, the package outline is generated by Computer-Aided Design (CAD).

This digital drawing is transferred to a piece of hardwood called a template.

The most sophisticated method of drawing the design on the template is to burn it on the wood surface using a state-of-the-art laser cutter.

The introduction of the laser in this process ensures greater accuracy in drawing on the moldboard.

Cutting dies are made using metal strips called rule or steel rule. The cutting rule is shaped into shape using a rule bender, which bends, cuts and grooves the steel into the desired shape.

Multiple cutting rules can be used in the die cutting process. Each rule has its own function and purpose, depending on the complexity of the package.

Some of the most common rule options are.

● Through-cutting: Through-cutting cuts the packaging material.

● Scores: Instead of cutting across the entire material, scores leave indentations or partial cuts at individual stress points.

● Indentation: Indentation is similar to a die forming a fold line on the packaging material. Unlike an indent, an indentation allows the material to bend inward by having two parallel stress points. Having two stress points allows for greater flexibility in the material.

● Perforation: Perforation involves indenting a row of holes along the design material. The design is not separated from the material itself, but can be easily separated along the perforation line.

Each rule is constructed to accommodate the thickness of the material and the size of the recesses.

Steel rulers are hammered into the template by hand. Various foam and rubber parts are then glued to the mold.

These pieces help the die to bounce off the corrugated board during the production process.

The die cutter firmly presses the die into the cardboard to create the cut out shape (remember the cookie cutter).

Depending on the complexity of the package design, this cutout has several lines, creases and folds that are used to assemble the package by hand.

Excess material is collected and recycled in its entirety.

Creating individual molds for each package is an expensive task. However, over time, multiple orders for the same package are offset as a one-time cost.

Die-cutting Technology

Die-cutting remains very analog and manual in nature. Despite the technology used in the process, the fastest way to mass produce custom packaging is still to use manually constructed cutting dies.

The two most popular die-cutting techniques used in packaging are

1. Flatbed die-cutting.

Flatbed die cutting is made from a flat rectangular piece of hardwood (mold board) that contains a unique mold shape.

It involves the use of a cutting die, which is firmly pressed into the cardboard by a flatbed machine.

Flatbed die machines have small blank sizes, so they are not recommended for larger designs. However, they are capable of producing complex, detailed designs such as small cuts, tight cuts and cut scores.

2. Rotary die-cutting.

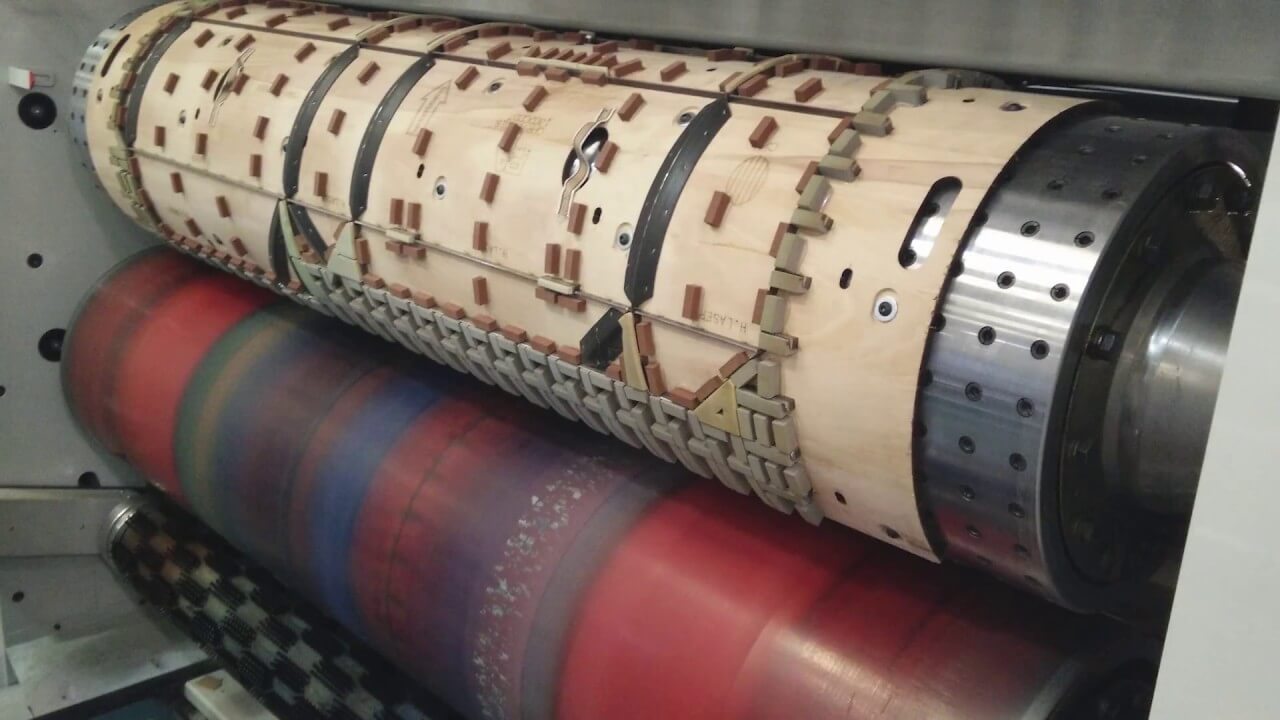

Rotary cutting dies are made from cylindrical presses and roll over the cardboard rather than pressing downward as with flat die-cutting machines.

Rotary die cutting is a faster process and is ideal for high volume production of simple designs.

评论

发表评论