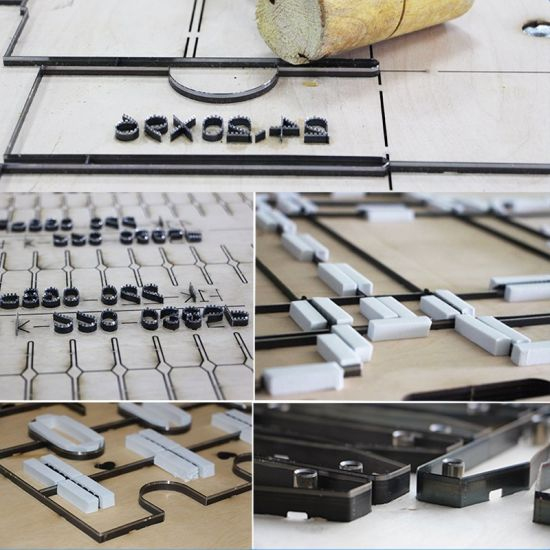

When producing packaging materials, a common process used by the industry is die cutting. Die cutting is a process where low strength materials (such as paper, corrugated fiberboard, cardboard, fiber, foil, plastic, etc.) are cut through a die. What makes the die an integral part of the process is its ability to cut pieces with a specified shape.

The consistency and accuracy of the die and die cutting process itself allows industries and their respective businesses to maximize aesthetically pleasing and unique packaging products. They can even obtain products with different shapes and profiles and multiple layers of complex cuts. In addition, they can get the packaging materials they need in a very short period of time, as the die-cutting process can produce large quantities of these materials at once.

With these benefits, companies that perform die-cutting processes can certainly help companies get the packaging materials they need. If you are looking to source a large amount of packaging materials for your business, then here are some of the reasons why a die cutting company can definitely help you.

Availability of Dies and Machines

Another reason why a die cutting company can certainly help you and other businesses that need a lot of packaging materials is because they already have all the machines needed for the die cutting process. There are several types of die-cutting machines on the market today. Fortunately, most of these machines are available at die cutting companies. In addition to the machines, die cutting companies can also produce dies based on your packaging material requirements. With these things in place, a die cutting company should be able to meet all of your packaging needs.

Knowledge and years of experience

It is almost impossible to beat the knowledge and experience of a die cutting company that has been around for a long time. Even though die-cutting technology is constantly changing, they can still keep up with the changing times. The companies that still exist today may only mean that they are truly thriving in their respective fields. It also means that they can easily master different types of machines, dies and cutting methods in a short period of time. They also know how to handle the die-cutting process for a variety of materials and produce an excellent end product in any given project.

Cost-effective die-cutting services

Packaging products can be expensive to produce. If you want to make them yourself, you may end up spending all your resources on this particular process. You will have to purchase all the machines needed for the die-cutting process. You will also have to acquire the materials to be converted. You even have to train some employees so that they can perform the process. All of these things take a lot of time, money and effort, which is not really cost effective for a business. Or, choosing a die-cutting company can save you a lot of money for your packaging needs.

For quality die-cutting services, call KINGVIDA.

评论

发表评论